Table Of Content

Remember, success lies in the details, and SOLIDWORKS helps you bring your vision to life with precision and excellence. Reach out to Conceptia Konnect to explore & understand how our cutting-edge solutions can help your organization. At PURE MACHINE DESIGN we are eager to innovate and develop machines or products from an idea let that be any field we are always ready.. • CNC machines are computer-controlled machines programmed to perform various tasks, such as cutting, drilling, and milling.

Vee Technologies’ extraordinary expertise

From the initial conceptualization phase to complete design, we provide you with end-to-end design support. TEAL's special purpose machines (Turnkey Solutions) incorporate cutting-edge technologies to maximize performance and functionality. We leverage advanced robotics, computer vision systems, artificial intelligence, and machine learning algorithms to enhance automation capabilities. These technologies enable our special purpose machines to perform complex tasks precisely, adapt to changing production requirements, and make real-time adjustments for optimal performance.

Counterfeit Apple Watch Knockoffs Hit China's Black Market - TIME

Counterfeit Apple Watch Knockoffs Hit China's Black Market.

Posted: Thu, 12 Mar 2015 07:00:00 GMT [source]

Understanding Special Purpose Machines (SPM)

Similarly, TEAL's special purpose machines have enabled precise component placement and soldering in the electronics industry, improving product reliability. SOLIDWORKS provides a comprehensive suite of tools that streamline the entire manufacturing process, from initial design to final production. By leveraging SOLIDWORKS’ powerful features, engineers and manufacturers can enhance productivity, optimize performance, reduce costs, and deliver high-quality SPM machines to meet the demands of today’s industries. Stay ahead of the competition by adopting SOLIDWORKS as your go-to CAD software for SPM machines manufacturing. SOLIDWORKS solutions numerous functions for verifying manufacturability, to reduce cost of the project.

Analysis (CAE)

This prototype undergoes rigorous testing to ensure its functionality, reliability, and performance. Once the prototype meets our strict quality standards, we proceed with the final implementation, where the (Turnkey Solutions) special purpose machines are installed and integrated into the client's production line. This automation not only saves time but also minimizes errors and ensures consistency across different documents. Manufacturers can generate accurate and up-to-date documentation, improving efficiency and reducing the chances of costly mistakes during production. In the intricate dance of precision and efficiency, Special Purpose Machine design emerges as the choreographer, orchestrating manufacturing processes with finesse.

Appearance Does Matter -- School Planning & Management - Spaces4Learning

Appearance Does Matter -- School Planning & Management.

Posted: Wed, 01 Jun 2016 07:00:00 GMT [source]

Packaging Design and Simulation Technology Market Booming Insights Global Forecast Outlook 2023-2030

We plan a holistic strategy for the spatial environment & user experience, starting with the client team, brand, & architecture. Full service architectural design firm located in Pawtucket, RI, focusing on residential projects throughout RI, MA and surrounding areas. • Injection molding machines create plastic parts by injecting molten plastic into a mold.

The evolution of SPMs reflects not only technological progress but also the inherent human drive to overcome challenges and elevate the standards of production. As we step into the future, the realm of SPM design promises to unlock new possibilities, redefine manufacturing paradigms, and shape industries with unparalleled precision and efficiency. Our dedication and technical expertise equip you with the necessary tools to face the increasingly challenging requirements of productivity. Whether you are looking at custom machine design or develop automated machines, our uniquely qualified experts can help you along the way. Are you tired of struggling with complex design processes and looking for a game-changer? Many Special Purpose Machinery manufacturing companies using our SOLIDWORKS complete product development solutions.

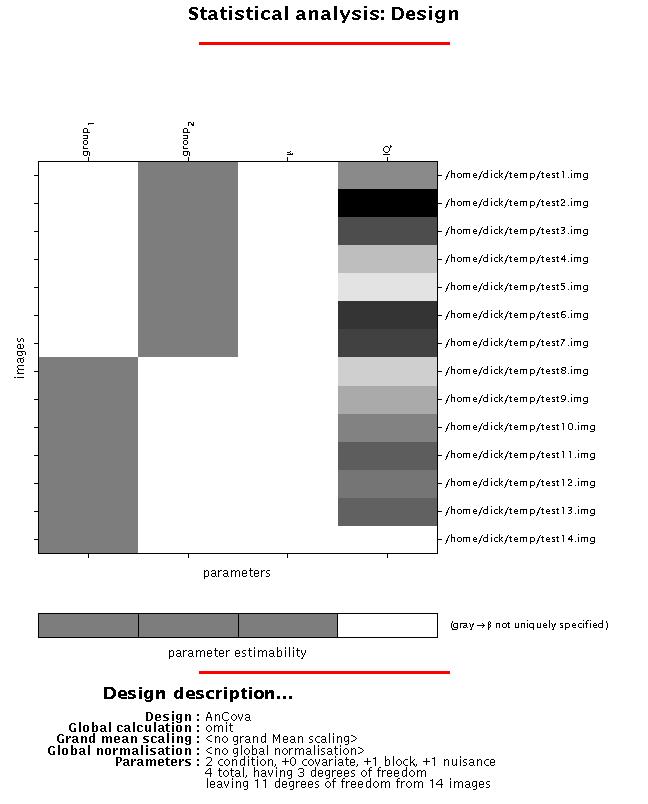

Then, as expected, this produces the same design matrix I would have gotten if I had entered the values for each covariate individually into the design specification! When working with a lot of subjects and/or a lot of covariates, this approach will substantially speed up your model specification. We are a global collaborative studio of designers, fabricators, and curators that tell your story with a human-centered lens through art curation, design, architectural installations, wayfinding, custom furniture, and environmental graphics. We work with a variety of clients including brands, public entities, museums, agencies, developers, architects, and designers. We provide designing and fabrication of Industrial Special Purpose Machines (SPMs) required to carry out a specific task in an efficient and automated manner.

By streamlining processes and eliminating bottlenecks, our solutions reduce cycle times, ensuring faster turnaround and improved customer satisfaction. Additionally, the precision and accuracy of our special purpose machines contribute to enhanced product quality, resulting in reduced defects and improved customer perception. Computer vision systems enable our special purpose machines to "see" and interpret visual information, facilitating object detection, quality inspection, and sorting tasks. With artificial intelligence and machine learning algorithms, our special purpose machines can learn from data, adapt to variations, and optimize performance over time. These advanced features enable TEAL's special purpose machines to deliver intelligent automation solutions, continuously improving productivity and product quality.

Our process involves a deep understanding of the client's requirements, thorough conceptualization, meticulous design engineering, prototyping, rigorous testing, and final implementation. We ensure that each step is carried out with precision and attention to detail, resulting in reliable and efficient special purpose machines. Automation and technological advancements have drastically changed the manufacturing industry. As SPM is not created on standard manufacturing programs, immaculate design is crucial to ensure product performance and safety. At Vee Technologies, we help develop technologically advanced machines that meet your specific needs by employing a highly specialized team that provides assistance with the design of the specialized tools and machinery. No matter how small or big your design requirements are, we are equipped to precisely cater to it.

1.Email us your project details, including pictures, location, and ideas at -sbm.com2.We'll set up a 30-minute virtual meeting to discuss your project and see if we’re a good fit for each other. This exploration of the evolution of SPM design aims to provide insights into the transformative journey of these machines, reflecting the dynamic synergy between engineering innovation and manufacturing demands. We are a collaborative studio of designers, fabricators, and curators that tell your story with a human-centered lens through art curation, design, architectural installations, wayfinding, custom furniture, and environmental graphics. That’s why we turn your ideas into clear 3D visualizations, allowing you to see your dream project before you commit to any changes.With our extensive experience in 3D rendering, we help make your vision crystal clear. We simplify the process by connecting you with great local architects and professionals from around the world.

Optimizing the design for manufacturing is crucial to ensure smooth production and assembly of SPM machines. By addressing these issues early on, manufacturers can streamline the production process, reduce errors, and enhance overall product quality. Special Purpose Machines (SPM) are machines which are designed to perform specific intent or tailor made to meet specific requirements and will not be available off the shelf. Special Purpose Machines (SPM) play a vital role in industries where repetitive tasks and high precision are paramount and mass production is required. To meet the demands of SPM machines manufacturing, engineers and designers need powerful software that can enhance productivity, accuracy, and efficiency. This is where SOLIDWORKS, a leading 3D computer-aided design (CAD) software, comes into play.